Quality Assurance

"Quality is the life of the company, and quality is the foundation of the company; Constantly pursue 100% quality assurance and provide customers with absolutely reliable quality products. "

The company's quality management system has been formulated based on ISO9001:2022, and has detailed operating procedures to strictly control quality. The purpose of quality management is to ensure that the quality of all components sold by our company is absolutely original. Establish a complete quality system:

1. Control quality from the source

1.1 It comes from qualified suppliers, strictly implements the supplier qualification review system, strictly implements the supplier filing approval system, and strictly implements the review of new supplier orders! The quality department works together with the purchasing department to review and rate suppliers.

2.Quality inspection

Strict inspection to detect problems before shipment!

2.1 Strictly implement classification and classification inspection regulations

2.2 Strictly inspect packaging, trays, tapes, labels, bodies, silk screens, pins, dimensions and other items.

2.3 The photos of the material or the brand that arrived from the previous company have labels and are strictly compared with each other.

2.4 For items that cannot be inspected by our company and need to be entrusted to a professional third party for testing, they need to be sent out for testing in a timely manner, and the test results must be communicated with the testing agency and compared with the specifications.

3. Traceable quality and customer satisfaction

3.1 In order to ensure that every shipment can be traced, the company has established an ERP system to enable one-to-one traceability from procurement to sales and delivery, thus ensuring quality traceability.

3.2 The quality department will work with the sales department to handle customer complaints and investigate customer satisfaction.

3.3 For product failures, promptly track the failure analysis with the original manufacturer and a third party, provide an analysis report, and collect customer evaluations of the analysis.

4. Quality process control

4.1 Each process introduction of the company must be reviewed and recorded by the quality department to ensure that it meets the principle of quality first.

4.2 The company's quality assessment, tracking and recording of the process ensures that the process is executed and the results are traceable.

4.3 Timely check whether the process is effective and record it. Process defects can be corrected and recorded in a timely manner.

Our professional quality inspection team will use advanced testing equipment to conduct visual inspection of the products. From packaging materials to component appearance inspection, all incoming materials need to pass strict and high-demand verification procedures to ensure that the goods provided to customers by Sennuo are high-quality original products.

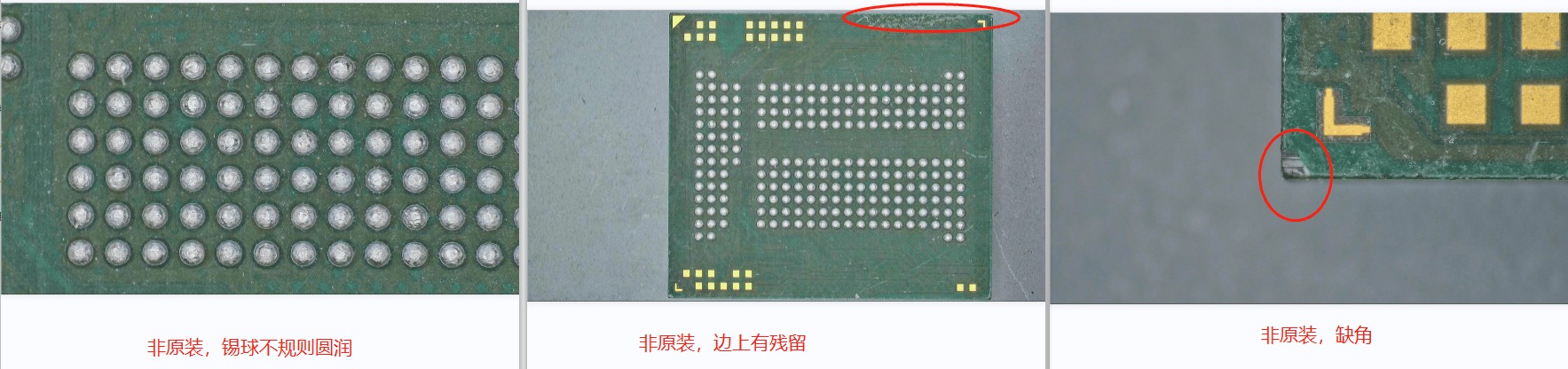

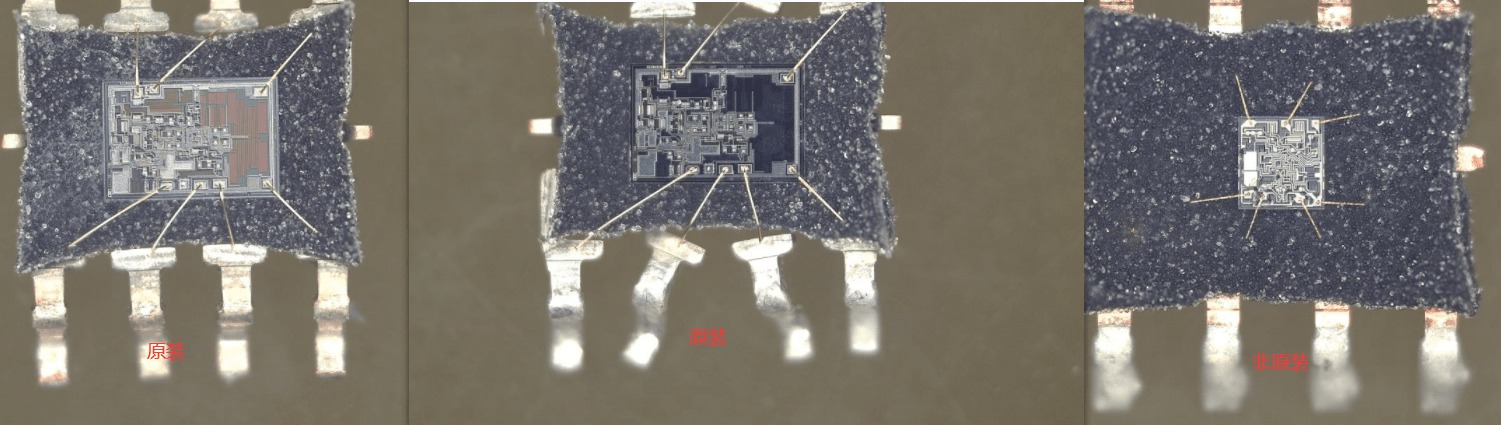

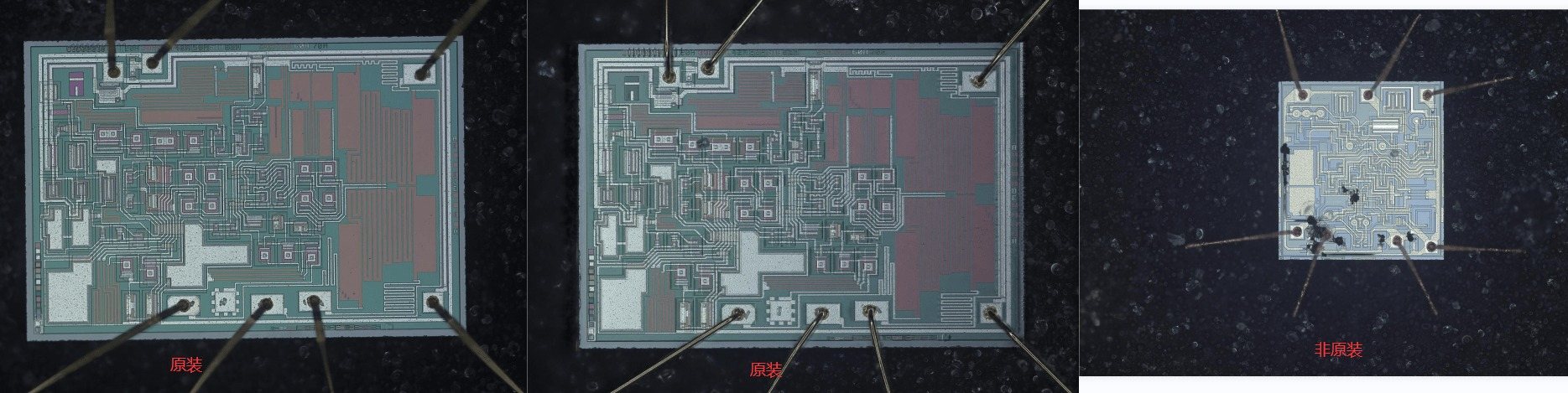

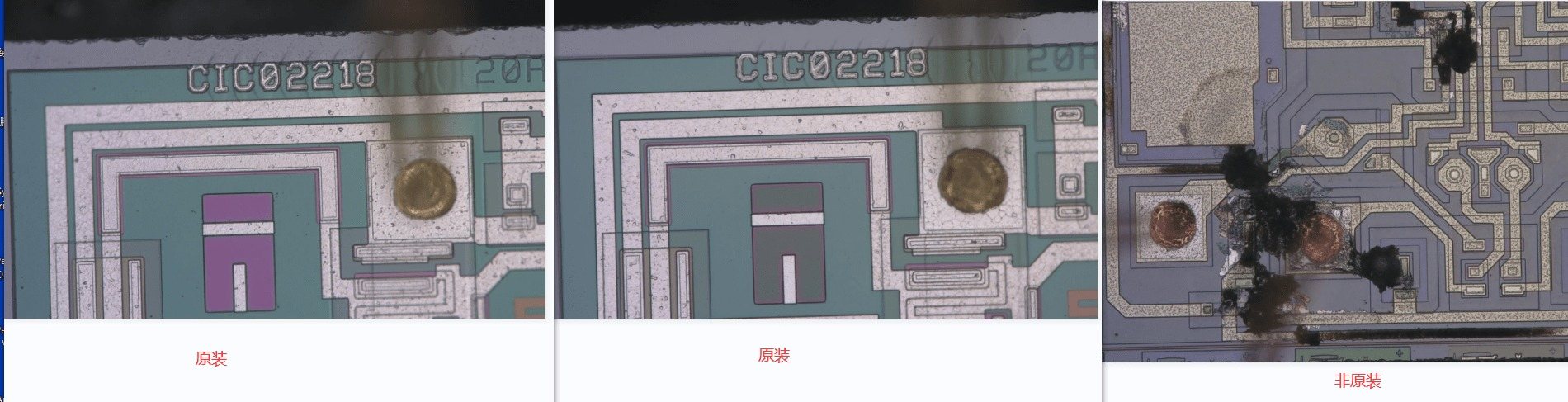

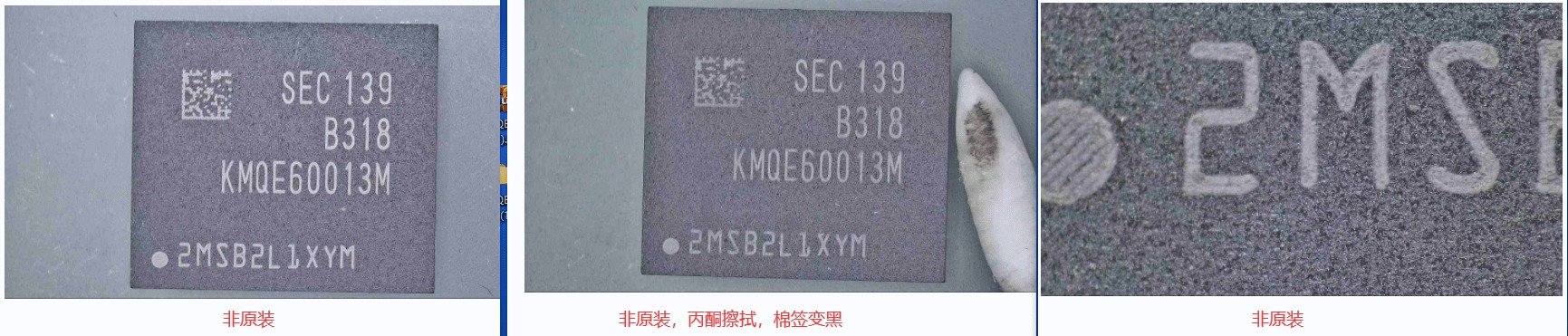

For supply sources without channel certification, we will also conduct cap opening inspection. The following is a comparison of original and non-original products from company history.

INA132U/2K5 晶圆

INA132U/2K5 晶圆 INA132U/2K5 晶圆

INA132U/2K5 晶圆 KMQE60013M-B318 正面

KMQE60013M-B318 正面 KMQE60013M-B318 背面

KMQE60013M-B318 背面